Scroll saw Scheppach

DECO SL

Published on: March 15, 2023

Reading time: 11 minutes

New purchase, new review! 🎉 Today I am telling you about the Scheppach DECO SL scroll saw. But let’s start right away with the basics to make it clear to everyone what we are talking about. And thus answer the question as easily as possible:

What is a scroll saw?

A Scroll saw is a special type of saw that because of the opportunity to disengage the blade can be used to cut inside the workpiece without having to change the contours or make a cut line to the desired inside point. It is mainly used to make curvilinear cuts and inlays of great precision even with sharp bends.

It is also called oscillating because of the cutting principle. Its short blade swings down and up to make the cut. For simplicity, we can say that it uses the same principle as a sewing machine.

The same manual variant, the fret saw, consists of a bow with a small blade attached to the end. This particular shape leaves the opportunity to be able to move easily within the inlays producing round, curvilinear or detail cuts of very small dimensions and with precision.

With a scroll saw you can normally cut a variety of materials such as:

- Wood

- Plexiglas

- Fiberglass

- Foam rubber

- Rubber

- Leather

- Cork

Deciding to buy an scroll saw or a fret saw is a decision basically related to the amount of work one has, or by how often one uses this tool, or what kind of work one is trying to do.

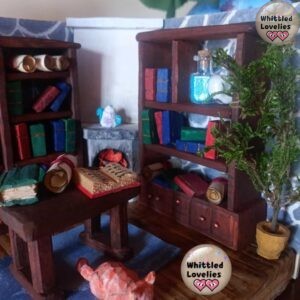

I had bought a bandsaw a couple of years ago, the Einhell TC SB 200/1, and I am still very satisfied with it. The need for this scroll saw came to me at the time when I decided to try my hand at making miniatures.

Essentially they may look like two nearly identical saws, but this is the mistake of many who buy a scroll saw and then complain that it is not accurate enough or lacks power. So let’s look at the main ones together:

differences between band saw and scroll saw

Let’s say that the first very big difference lies precisely in the peculiarity of the scroll saw that I described to you just now, which is the ability to get to the heart of our work and be able to saw quietly inside it without modifying other parts to get there.

In addition, it is important to remember that the band saw has a long, continuous blade that runs essentially like a belt, while that of the scroll saw is oscillating from bottom to top. It goes without saying that the types of cuts that can be made are vastly different. Just as the precision and cleanliness of the cut is also markedly different.

Another important difference is the compliance of the machine itself. A band saw is to be used from a standing position, and the workpiece is to be pushed toward the blade based only on the handling of the workpiece rather than its actual size. The only limitation is the size of the worktable, which allows a maximum width of the workpiece of about 15 cm on the left side, after which you go to hit the saw frame.

The scroll saw, on the other hand, has the bow, also known as the swan neck, which instead allows us to cut or move in cuts with pieces about 40 cm before touching the machine. Plus it is a saw that is to be used while seated, you push the piece toward the blade that is in front of you, it has no side impediments only, the inches that distance us from the swan neck.

Next we turn to power, referring of course to my saws, it ranges from a 250 W of the band saw to the modest maximum 90 W of the scroll saw. This is because while it is a full-fledged saw, it is not suitable for woods that are too dense or particularly high. It is a saw that gives its best in sawing at most 2 cm high despite its claimed 5 cm.

Being underpowered with each cut with hard or particularly thick woods results in fatigue and less and less precise cutting and thus more likely to split the blades or overload the motor.

To finish the roundup of the main differences, we can in addition say that the scroll saw is not very accurate in straight cuts since there is no way to apply a ruler to the work surface, which normally has a rounded shape. One has to rely on manual dexterity or the cuts of a band saw.

Having clarified these important points, I will now go on to describe my Scheppach DECO SL scroll saw, starting with a bit of data:

the company

Scheppach is a German brand of woodworking machinery and garden equipment in Ichenhausen, Bavaria, Germany. The company was founded in 1927 by Josef Scheppach in Niederraunau, also in Bavaria, as a family business. Originally they produced only agricultural machinery and circular saws for firewood.

In the following years they decided to abandon the production of agricultural machinery, and in the mid-1970s production began to focus only on the development and production of woodworking machines. To date, it has expanded its historic headquarters in Ichenhausen and has also expanded its market to France and Australia. It has also recently opened a complementary line to woodworking, namely gardening equipment.

The steady growth of this company has led it to become an undisputed specialist in the field, continuing to expand its range of machines and accessories with great success to the present day.

Based on my satisfaction in buying German tools, I felt that this saw was right for me. And always paying attention to the price, I could not fail to notice the excellent value for money as well. For only 99 euros I could not ask for better.

Which model to buy?

The only major difficulty I found in finding information online is that there are so many models of this saw so it is a little difficult to compare, but I still found a way to help you a little bit in choosing the best one for you.

First thing to take into consideration is the price, similar prices, say in the range of 100 to 200 euros and similar names it is the same machine body (or with small variations) and what changes are the accessories. For example:

- DECO XL

- Has the foot switch

- FLEX SL

- has a flexible shaft for precision work like the one supplied with Dremels to which drill bits or Carbide Burr Set and other accessories can be attached

- DECO-XLST

- 120 W power, has foot switch and a stand where it can be mounted to ensure greater stability

- SD1600V

- 120 W power and reaches up to 1700 rpm, has a flexible blowing nozzle and a larger led lamp

Also considering these that I have called accessories, but are actually included in the purchase of the machine, is a good idea given the low prices.

What I think should be evaluated more carefully is where you are going to place it in your workshop. If it is on a clear surface and you can stand next to the saw to work, it is interesting to have the flexible shaft for precision work, but consider that you will have about 1 meter of ease in movement.

In short, many solutions all valid, but I, who had no special needs, opted for the most basic version. In fact, the Scheppach DECO SL scroll saw only comes with the led lamp and speed controller.

Technical details

Here is a roundup of technical information so that it is easier to understand what tool we are dealing with and to compare it with similar ones:

Technical specifications

Electrical Motor:

230-240 V | 50 Hz

Power consumption:

70 W S1

90 W 15 min S2

Stroke Speed:

550-1500 rpm

Running movement:

18 mm

Blade length approx:

127 mm

Protrusion:

405 mm

Max cutting height at 45°:

20 mm

Max cutting height at 90°:

50 mm

Dimensions:

650 x 255 x 340 mm

Swiveling bench:

0 ° a 45 ° leftward

Bench size:

254 x 407 mm

Suction connector diameter:

34,5 mm

Type of protection:

IP20

Emission values

Acustic pressure level L pA:

80,4 dB(A)

Uncertainty K pA:

3 dB

Acustic power level L WA:

93,4 dB(A)

Uncertainty K WA:

3 dB

Content

Oscillating scroll saw

Saw blade protection

Venting hose

Saw blades:

2

Allen wrench:

2,5 mm

3 mm

Batteries:

2x AAA

Product weight:

8 kg

As you may have noticed, this model, but as well as almost all other similar ones, has the ability to deal with cuts with inclinations from 90° to 45° with a very handy square placed on the underside of the work surface.

In many reviews, I noted that the biggest problems encountered by buyers were regarding the vent hose, blade insertion, and too-easy blade breakage.

I can tell you that I have not found any of these aspects to be a problem. Of course, you always have to think about the use of the machine, many times we are the ones who want to use a particular tool for jobs for which it was not designed…

However, I tell you my impression and experiences after 2 months of almost daily use.

Review and advice

Assembling the machine right out of the box is very easy. Just fasten the top and the sliding feet called pressers with the provided Allen screws. After that put the batteries, also provided, into the led lamp. And finish by attaching the vent tube.

This in my opinion is a little too small and with too much desire to slip off. Even inserted all the way through, the next day you find it detached again. Working when it is detached is almost impossible, too much sawdust ends up on the cut and you can no longer see what line to follow. The solution to this inconvenience is simple, just a clamp and it will never move again.

Just to be clear it is not that this tube has a suction or venting force that comes from the machine, you necessarily have to attach a vacuum to the nozzle and use them at the same time. Only in this way can you avoid having so much sawdust.

I, who had no more space, put the saw in the house and was very worried about the noise and the dust that would inevitably spread all over the house. Plus something that is not encouraged at all, I used an old household vacuum cleaner as a dust absorber. I just plugged it in with adapters and it works beautifully.😇

The noise then, is not that excessive at all. No complaints from the neighbors, who hear the vacuum cleaner more than the saw itself. Of course it’s an electric saw it’s not like you can imagine it making no noise at all, but respecting the direction of the wood and not sawing excessively dense or thick pieces no problem. Still better than the band saw, though.

I really recommend using it while sitting, it is the best position, the most comfortable position for doing long and complicated work and the position from which you will always have better visibility. The LED light is also essential in a well-lit environment and is adjustable. Dust never ends up in your eyes thanks to a plexglas guard in front of the blade.

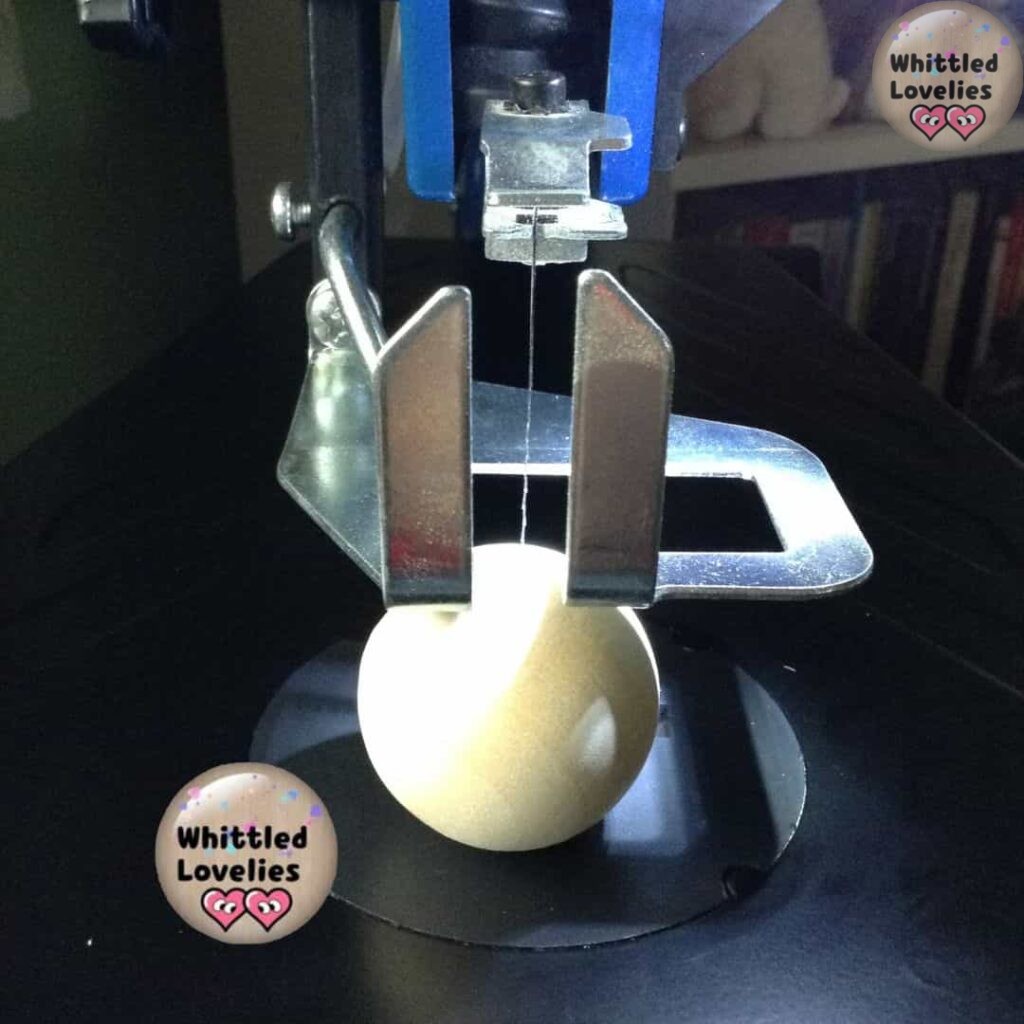

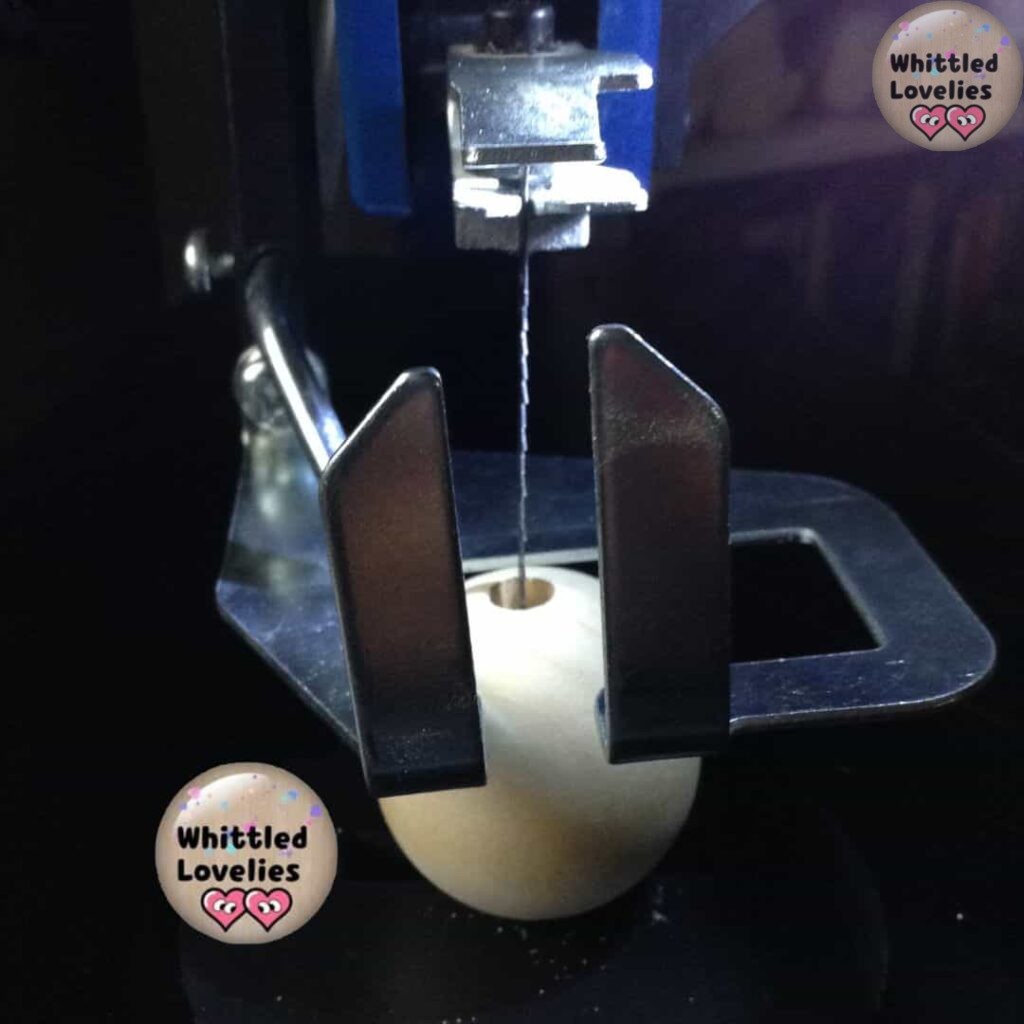

The pieces must be walked to the blade gently and slowly. One really has to imagine oneself in front of a sewing machine. On the swan neck there is a tensioner for the blade, which in my opinion, on non-straight cuts, is best left taut but not excessively so.

In two months I have yet to break a blade, and despite the fact that the two supplied are identical, I decided to buy a set with different numbers of teeth. This is because for every job it is correct to match the right blade, so

What kind of scroll saw blades to choose?

First, always remember to choose the right type of blade for the material you are going to cut. Speaking exclusively of wood blades there are a few things to keep in mind:

The sizes, hooks, dimensions, and teeth

Normally, scroll saws mount universal sizes that are meant on a standard 130 mm size.

The hooks or fasteners can be smooth or with pins, normally you can use both with adapters. The DECO SL works perfectly with blades with pins. Always remember that the blades should be mounted with the pins down because the blade cuts when going down and slides when going up.🤓

Blade sizes are generally numbered from below 0 up to 12. Those below zero are very thin and are normally used more on fret saws, but there is nothing to stop you from trying to use them on the electric saw as well. They are mainly recommended for inlays that must fit together perfectly like a jigsaw puzzle.

The more the blade size increases (thus the number), the more consequently the recommended cutting thickness increases. These are numbers that are given by the manufacturers but in general we can say that with a No. 1 blade we recommend thicknesses up to 4 mm, then we go up with each blade size 2 mm more cutting thickness. So with No. 2 we recommend 6 mm, with No. 3 8 mm cut and so on.

Teeth count is normally denoted by the acronym TPI (teeth per inch). More teeth correspond to thinner and narrower cuts, thus slower cutting, more control and greater precision. The more you decrease the amount of teeth, you proceed faster in cutting but lose precision and the cut becomes coarse.

To obviate the limited size by the swan neck of the machine, blades called omnidirectional , spiral or helical blades can be used, which have the advantage of cutting in all directions because the teeth are fixed in a spiral around the axis of the blade. With these, however, you have more irregular, dirty and wide cuts and they are the most difficult to use in straight cuts.

Finally, there are blades with inverted teeth. They have teeth up to half of the blade facing down and the other half facing up. this way they cut accurately and cleanly even in the lower part of the workpiece but if not used carefully they are easy to break and can deburr excessively at both the top and the bottom.

Using pressers correctly and always is one way to avoid blade breakage. Without the proper pressure on the work surface, the workpiece swings excessively and embeds in the wrong way in the wood. Not to mention the noise! 😂🤦🏻♀️

By using these tricks and working without being in a hurry, feeling when the machine is straining and trying to adjust the thrust force and speed of the machine, it is easier to be able to do good jobs and split very few blades. In the case is not a drama they cost really little and the changeover is not at all as difficult as you might imagine.

As in all things the important thing is to give yourself time to learn and only with practice will you reach the right mischief. I hope I still gave you some useful tips even if you are already experienced!

Pretty obvious conclusion, I recommend the purchase of this Scheppach scroll saw. If in time I regret the purchase rest assured I will talk about it in another article! For now I will leave you to your trials with a very short video of my latest miniature work totally made in wood with knife and the scroll saw.

And that’s it for this month as well, but don’t despair, there are more articles to read from the EQUIPMENT category! For example I tested for you the Focuser Carving knives, click the link to read the article! Bye, see you soon! 😘😘😘

This is an article written by a human for humans!

All articles in the blog are written by me. No contributors, no people paid to write content for me.

Posts written by guests or friends of the blog are marked under the title with the words “guest post.” These are friendly collaborations, contributions to the carving community.

No AI (artificial intelligence) support is employed in the writing of blog articles, and all content is made with the intent to please humans, not search engines.

Do you like my content?

Maybe you can consider a donation in support of the blog!

Click on the button or on the link Ko-fi to access a secure payment method and confidently offer me coffee or whatever you want!

From time to time, in articles, you will find words underlined like this, or buttons with the symbol 🛒. These are links that help deepening, or affiliate links.

If you are interested in a product and buy it suggested by me, again at no extra cost to you, you can help me cover the costs of the blog. It would allow me to be able to give you this and much more in the future, always leaving the content totally free.