M-stein carving knives

Published on: May 15, 2024

Reading time: 7 minutes

Hello everyone! Welcome or well and truly back! Today I want to talk to you a little bit about knives again! The topic is always hot and appreciated a bit by everyone in the community and so welcome to make space for a more specific review regarding the knives that I have always told you are my favorite, the M-stein carving knives!

If you are a veteran of the blog you will know well that whenever we have touched on the subject of knives I have always praised these knives, if not only for the quality/price, they were also my first serious knives and I am particularly fond of them.

What I like most about them is that they are always in use, for years now, and still they largely hold their own against all those that have come after them. Some time ago I had done an article comparing similar models of different brands in the search for the best carving knife.

My conclusion had been that everyone has merits and demerits, but in the end the real best is always the one you try and remain inextricably attached to. Sometimes it makes me smile when I have multiple knives on my work table and maybe I just reach for one with my sense of touch, without looking, and in the end I always find my trusty M-stein No. 2 knife in my hands!

But let’s move on now, to talk a little bit about how this company, I would like to emphasize, totally family-run, began its history and how it has evolved over time to the present.

History

Peter is an accomplished stonemason, sculptor, and stone restorer. In the 1980s he combined this great passion of his with teaching, and began his career as a teacher at the school of art and design in Košice (a town in eastern Slovakia near the border with Poland, Ukraine, and Hungary).

Membership in the school is good so, in the late 1980s, they realize with a colleague that they do not have enough tools for everyone, and there would also be a need to invent new tools for sculptors. So they decide to open a metalworking section within the school as well. And it was in this workshop that the first equipment and the production of numerous types of chisels were born.

In the winter of 1989, Slovakia experienced the “Velvet Revolution” (nežná revolúcia) that led to their liberation from Russian oppression and the dissolution of the communist Czechoslovak state. Later, in 1993, this process finally ended with the political division between the Czech Republic and Slovakia.

From this important moment, citizens found themselves able to experience a much-needed freedom and with it the opportunity to finally be able to open private companies as well. And so in 1994, Peter founded M-stein.

The name comes from the M taken from the last name of the founder, Peter Mészáros, and the word stein, which simply means stone.

From this time Peter devotes himself almost completely to his new company and goes to numerous trade fairs abroad making contacts and learning as much as he can. Here he realizes that not many people in the area of the Czech Republic and Slovakia produce these kinds of tools in an artisanal way.

He soon sensed the potential of also starting a production of woodcarving tools. Always in contact with restorers, woodworkers and colleagues, he gathers suggestions on how to create tools that can facilitate everyone’s work.

To this day their son Pavol, an architect, is also in the company, and with the vision of both of them they carry on the work leaving more time for Peter to complete some absolutely noteworthy restoration work.

His work has been done on many buildings and churches in the region, but surely the most impressive was the restoration of the largest church in Slovakia: Dóm svätej Alžbety, Saint Elisabeth Dome, the largest church in the state and the easternmost Gothic cathedral in Europe, in Košice.

Photo of visitkosice

Production

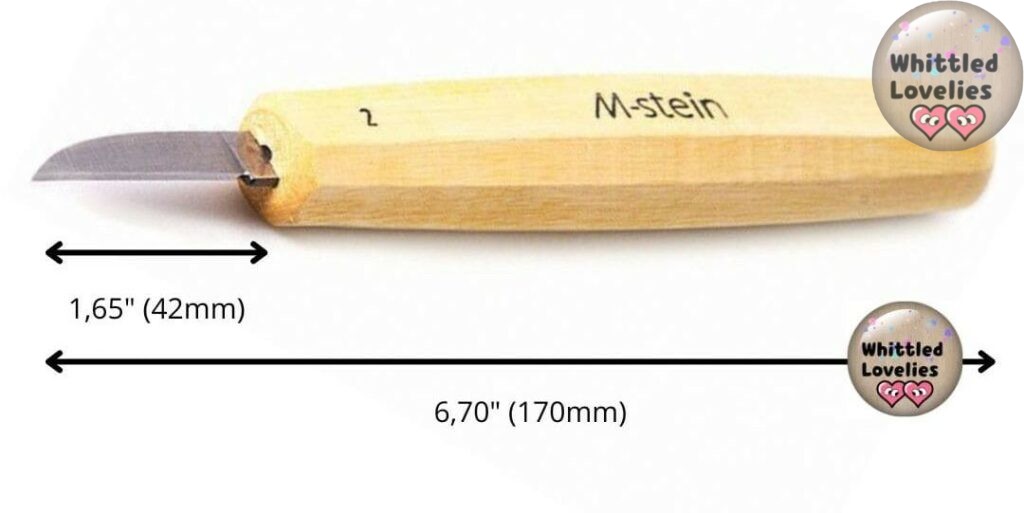

To date, M-stein’s production is mainly focused on tools for woodcarving, linocutting and power carving. It now counts on about 500 items divided between knives, gouges, hatchets and accessories.

Each tool is hand forged from tool steel and heat-treated to a hardness of 60°-61°HRC. The handles, on the other hand, are made of unlacquered hornbeam wood and are absolutely cool, dry and comfortable.

Sharpening

M-stein knives and other tools, arrive already perfectly sharp, and for a while we do not have to worry at all except to hone from time to time simply with a bit of paste and a strop.

I, after years of owning these knives, must tell you that I have never really sharpened them, but always just razored them! Granted, I treat them pretty well and use only soft-to-cut wood, mainly basswood. But maybe now would be a good time to try following the advice Peter himself gives on sharpening his knives. (Valuable and useful advice for sharpening all knives with similar HRC as well).

HAND SHARPENING

Gouge or knife blades that after regular sharpening are still very blunt, have a rounded blade, or are jagged should be sharpened with an abrasive stone.

We run the cutting edge of the tool in circular motions over the stone with water.

For better rinsing of debris from the stone, a few drops of detergent or fine mineral oil, alternatively diluted with turpentine, should be added.

We sharpen the cutting edge at an angle of 25°-30° (for soft wood a less pronounced angle).

We sharpen only from the underside until the damaged blade is straightened and until a burr appears, a thin soft piece of steel at the end of the cutting edge.

For sharpening, we use a harder stone with grit around 150, then switch to a finer stone with grit around 350.

A very fine sharpening stone (Rozsutec, Arkansas, your choice of synthetic corundum) is used to remove the burr. Fine sandpaper over 1000 grit can be used in place of sharpening stones.

Finally, you polish the edge on the skin using a polishing paste (silicrome or other metal polishing paste).

Throughout the process we maintain the selected cutting angle.

For less sharp or non-jagged edges, simply sharpen with a very fine stone and finally polish on the leather.

After sharpening, it is recommended to clean the sharpening stones to prevent corrosion of the steel settled inside them.

The inner side of the blade is polished, and on this side it is not necessary to sharpen the tool. Simply sharpen them at the end on the leather adapted to the shape of the blade.

If the tools are damaged or rusted, we need to sharpen this side as well, using shaped sharpening whetstones or very fine sandpaper on the shaped piece.

ELECTRIC SHARPENING

It is much faster to sharpen tools on an electric grinder with a carbon disc.

Low-speed grinders, whose discs are partially immersed in water that ensures their cooling, are suitable.

Using conventional sharpening machines at high speed without cooling can easily cause the edge to overheat and turn blue, so the blade loses its original hardness. So this part needs to be ground.

After sharpening on a carbon disk, we sharpen it at higher speed on a felt disk, on which we spread polishing paste.

The cutting edge is placed on the disc in the direction of the disc’s rotation, so that it cannot cut into the disc itself.

The polished inner side of the blade is suitable for sharpening with a felt disc, which fits the shape of the chisel or the blade.

I wish you great success and hope our tools bring you more pleasure in your work.

Peter Mészáros

Don’t miss this opportunity!!!

I have prepared a video demonstrating the use of these fabulous knives, with a simple little project that can be done in 20 mintutes. You can find it in the Youtube channel along with other, I hope, interesting videos that I am slowly trying to make to populate the channel a bit more!

Every article I do, when I cite sources, I always notify those directly involved. I did so again this time and big surprise!!! 🎉 At M-stein they decided to give me an amazing opportunity! A special and exclusive discount for you, my dear readers! 😎

I am so happy!!! 🤩🤩😍

July 1, UPDATE:

In the first 15 days of the article’s release, the 10% discount granted by M-stein was greatly appreciated. Many asked to extend the promotional period but unfortunately it was not possible, it was a special occasion.

But they offered us a discount that will last until June 2025!

This is a very special opportunity to try these products! As you will see they are also at a fabulous price and great value for money. Be sure to take advantage of them! I am sure you will find yourself as well as I did!

And what can I say? I’m incredibly happy to be able to be an ambassador for a company that I’ve adored for years and support a beautiful family business where things are still handcrafted the way they used to be. So many thanks to Peter and all of M-stein, I hope I can contribute a little bit to your well-deserved success!

We guys will be back here next month for another article! If you are still looking for information and also want to learn more about other brands of knives and woodcarving tools you will find them in the Equipment category! Happy searching! Bye! 😘🤗

This is an article written by a human for humans!

All articles in the blog are written by me. No contributors, no people paid to write content for me.

Posts written by guests or friends of the blog are marked under the title with the words “guest post.” These are friendly collaborations, contributions to the carving community.

No AI (artificial intelligence) support is employed in the writing of blog articles, and all content is made with the intent to please humans, not search engines.

Do you like my content?

Maybe you can consider a donation in support of the blog!

Click on the link Ko-fi to access a secure payment method and confidently offer me coffee or whatever you want!

From time to time, in articles, you will find words underlined like this, or buttons with the symbol 🛒. These are links that help deepening, or affiliate links.

If you are interested in a product and buy it suggested by me, again at no extra cost to you, you can help me cover the costs of the blog. It would allow me to be able to give you this and much more in the future, always leaving the content totally free.